Aramid Fibers

Introduction

In the research labs at E. I. Du

Pont de Nemours & Company, Inc., in 1965 two research

scientists, Stephanie Kwolek and Herbert Blades, were working in a corporate lab

to create a new fiber. The technology they developed had enhanced strength, was

lightweight and very flexible. The new

fiber, called Kevlar, could be offered in many different forms. One of the most popular uses of Kevlar came

in the form of bullet-resistant vests that police officers have relied on for

over 25 years. The greatest attribute of

the fiber was strength it provided in a very lightweight form, that was both

comfortable and gave a wide range of movement to the officer. This discovery came from a very chemically

similar compound called Nomex. The

creation of this fiber gave birth to thermal technology, which combined heat

and flame resistant properties along with advanced textile characteristics.

The production of aramid fibers

known under their trademark names Kevlar® and Nomex.® have unique and

beneficial properties. These two aramids

are similar in basic structure and are sometimes produced in the same

production plants. The difference is in

their structure, Kevlar® is a para-aramid while Nomex® is a meta-aramid. An aramid is a polyamide where at least 85%

of the amide bonds are attached to aromatic rings. The first aramid produced was called Nomex®

introduced by Du Pont in 1961. For this

report we will dissect each fiber separately.

Kevlar®

History

Kevlar® was originally developed in

the 1960’s with the chemical name of poly-paraphenylene terephthalamide; but

chemists to this day still do not understand why the fiber is so strong. First introduced commercially by Du Pont in

1972, the fiber has similar competitors in Twaron and Technora. Kevlar was originally developed as tire chord

material for belts and carcasses in radial tires. The common uses for Kevlar®

today include: adhesives and sealants,

ballistics and defense, belts and hoses, composites, fiber optic and

Electro-mechanical cables, friction products and gaskets, protective apparel,

tires, and ropes and cables. These

include items such as trampolines and tennis rackets.

Characteristics

The

resounding characteristic of Kevlar is its remarkable strength. This very strong fiber has made its biggest

impact in the ballistics defense where it’s used in bulletproof vests. It is stronger than fiberglass and five times

stronger than steel on a pound-for-pound comparison. The high tensile strength and modulus are

characteristics of all the Kevlar fibers, with Kevlar 49 and Kevlar 149 showing

an even higher modulus. Kevlar’s chains

are ordered in long parallel chains, and the key structural feat is the benzene

aromatic ring that has a radial orientation that gives the molecule a symmetric

and highly ordered structure that forms rod-like structures with a simple

repeating backbone. This creates an

extremely strong structure that has few weak points and flaws. The table provided below shows the various

characteristics of Kevlar fibers and where compiled from both the Chemical

Economics Handbook and Encyclopedia of Chemical Technology, Vol. 19.

|

Properties of Commercial Aramid Fibers |

|

|||

|

|

|

|

|

|

|

Fiber type |

Density, (g/cm3) |

%Elongation |

Modulus, Gpa |

Tenacity |

|

Kevlar 29 |

1.43 |

3.6 |

70 |

20-23 |

|

Kevlar 49 |

1.45 |

2.8 |

135 |

20-26 |

|

Kevlar 119 |

1.44 |

4.4 |

55 |

N/a |

|

Kevlar 129 |

1.45 |

3.3 |

99 |

N/a |

|

Kevlar 149 |

1.47 |

1.5 |

143 |

18 |

|

Nomex |

1.38 |

22 |

17 |

5.8 |

Notice the much higher modulus and lower %

elongation from Kevlar 49 and 149.

All of the general features of Kevlar listed

here are taken from Du Pont’s web homepage:

·

·

High Tensile Strength

at Low Weight

·

·

Low Elongation to Break

·

·

High Modulus

(Structural Rigidity)

·

·

Low Electrical

Conductivity

·

·

High Chemical

Resistance

·

·

Low Thermal Shrinkage

·

·

High Toughness

(Work-To-Break)

·

·

Excellent Dimensional

Stability

·

·

High Cut Resistance

·

·

Flame Resistant,

Self-Extinguishing

These features give a good picture on why

Kevlar is a popular choice for all protection and casing purposes; low

conductivity and self-extinguishing, flame resisting characteristics have made

it a component for wire casing and fire fighting protection. The interesting thing is that it has a high

elongation at break at around 4%, however it is commonly used in fiber that

includes Lycra spandex.

Chemistry/Manufacture

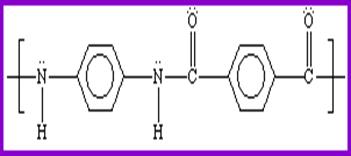

KEVLAR® is a crystalline molecule

that consists of long molecular chains that are highly oriented and show strong

intermolecular chain bonding in the para position. It is made from the reaction of

para-phenylenediamine (PPD) and molten terephthaloyl chloride. The production of p-phenylenediamine is

difficult because of the diazotization and coupling of aniline. The reaction compounds involving the

production Kevlar using p-phenylenediamine and terephthaloyl chloride is shown

below.

style='mso-tab-count:2'>

The PPD and the terephthaloyl chloride are

reacted by using N-methylpyrrolidone as a reaction solvent. The structure for

poly-paraphenylene terephthalamide is shown below.

The resulting polymer is filtered,

washed and dissolved in concentrated sulfuric acid and is extruded through

spinnerets. It then passes through a

narrow duct and goes through the wet spin process where it is coagulated in

sulfuric acid. The filament can take two

different paths at this point. It can be

formed into a yarn, washed and dried which is wound into spools that produces a

modulus of 400-500 g/denier. Conversely, the filament can go under further heat

treatment with tension and produce a fiber with a modulus of 900-1000

g/denier. The end product can take

several forms. It can form filament

yarns, pulp, or spun-laced sheets and papers.

Economic Impact

The production of fibers like Kevlar

is really an oligopoly. Du Pont, being

the producer of Kevlar is the largest producer para-aramids in the world. Du Pont currently produces in three

countries: the United States, Northern Ireland, and Japan. These three sites have a production capacity

of 65.9 million pounds of the 94.7 million pounds of total aramid fibers

capacity. The other producers are Aramid

Products in the Netherlands, which makes Twaron and Teijin Ltd of Japan, who

makes Technora. Russia also produces a

very low percentage of para-aramids called Fenylene.

Below is a production table for all para fibers

in the last two decades. As of 1998,

Kevlar accounted for 85% of the global market of para-aramid fibers. Production in Western Europe and Japan has

jumped up greatly in the last ten years.

All of the production in the United States is done by Du Pont to produce

Kevlar. Also Du Pont accounts for about

one-third of the total production in Europe and about one-half of the

production in Japan.

|

World Production of Para Fibers (millions of pounds) |

|||||

|

|

|

|

|

|

|

|

|

United States |

Western Europe |

Japan |

Russia |

Total |

|

1979 |

13 |

0 |

0 |

<1 |

13 |

|

1986 |

29 |

<1 |

0 |

2 |

31 |

|

1988 |

29 |

6 |

<1 |

2 |

37 |

|

1990 |

29 |

10 |

1 |

3 |

43 |

|

1991 |

26 |

10 |

4 |

2 |

42 |

|

1992 |

23 |

11 |

7 |

2 |

43 |

|

1993 |

23 |

12 |

7 |

2 |

44 |

|

1998 |

31 |

16 |

8 |

3 |

58 |

***Figure from this table taken from the Chemical

Economics Handbook

Consumption of para-aramids in the three major

regions: United States, Western Europe, and Japan hit 39 million pounds in 1993

and increased to 47 million pounds in 1998.

The growth of Kevlar has not yet met it’s full

potential. The rapidly growing uses for

Kevlar include ballistic protection in Western Europe, truck and bike tires,

and with it’s lightweight dielectric properties, tension reinforcement for

fiber optic above ground cables and protective coverings for underground and

underwater fiber optic cable. Of all the Kevlar imported; 50% is used for tire

manufacture, while the rest is used for fiber optics, brake materials, and for

industrial fabrics. Dunlop Tire Corp.

has begun to make a tire that is 30% lighter than traditional tires and that

eliminates the steel belt and bead wire.

The only catch that’s holding back a full scale use of Kevlar is its

price; 1,500 denier is commonly used for tire cord, hoses and belts costs $12.00

per pound, while the other common grades of Kevlar range in the $13.00 to

$15.00 range. Outside of the U.S., the

same 1,500 denier fiber costs $23.00-27.00 per pound. Even with the expanding market as it

currently is, widespread growth will not be realized until the costs of

production falls.

Nomex®

History

NOMEX® was developed by DuPont for

in 1961 for products that needed dimensional stability and good heat

resistance. Nomex® products are used in

protective apparel, hot gas filtration, and automotive hoses, electrical

insulation, aircraft parts, and sporting goods.

Characteristics

The properties of Nomex include

great electrical insulation properties at high temperatures. Nomex does not flow or melt upon heating and

doesn’t degrade or char at temperatures until well over 370 degrees

Celsius. The compound that is usually

found in fire-fighters coats and airline seat covers is Nomex III, which is a

composite of 95% Nomex and 5% Kevlar.

The Kevlar adds stability and tear resistance to the material. The general properties of Nomex are listed

below.

·

·

Heat and Flame

Resistant

·

·

High Ultraviolet

Resistance

·

·

High Chemical

Resistance

·

·

Low Thermal Shrinkage

·

·

Formable for Molded

Parts

·

·

Low Elongation to Break

·

·

Low Electrical

Conductivity

This properties cause paper made by Nomex to be

stronger and tougher than regular cellulosic papers. Overall, Nomex® is both thermally and chemically

very stable. The difference between

Kevlar and Nomex is the location of the amide linkages on the aromatic

ring. Those differences cause Nomex to a

lower modulus and tensile strength and a higher elongation and solubility in

organic solvents.

Chemistry/Manufacture

Nomex®, is a meta-aramid fiber

created by Du Pont in 1961. The chemical

name of Nomex is poly (m-phenylene isophthalamide), which is produced from the

reaction of m-phenylenediamine and isophthaloyl chloride whose structures are

shown below.

The solution is dry spun through

spinnerets. The remaining solvent is

evaporated, the filament is washed and wound into tow, heated, and finally

stretching into rolls at a temperature of 150 degree’s Celsius. Nomex can be produced as a continuous

filament yarn, staple, spun yarn, floc, pressboard, paper, needle felt, or as a

fabric. Next we will take a look at the

economics of producing Nomex.

Economic Impact

The growth of meta-aramid fibers has

grown steadily over the last 10 years. At the same time the U.S. share of production

has fallen 19% from 1990 to 1998 from 81% to 62%. This drop is largely due to the growth of

production in Western Europe, from no production in 1990 to 21% of the market

share in 1998. The table below shows

production patterns of meta-aramids since 1979.

|

World production of Meta-Aramid fibers (millions of pounds) |

||||||

|

|

|

|

|

|

|

|

|

|

|

United States |

Western Europe |

Japan |

Russia |

Total |

|

1979 |

|

12 |

0 |

<1 |

<1 |

12 |

|

1986 |

|

18 |

0 |

2 |

1 |

21 |

|

1988 |

|

20 |

0 |

2 |

2 |

24 |

|

1990 |

|

21 |

0 |

4 |

2 |

26 |

|

1991 |

|

23 |

0 |

4 |

1 |

28 |

|

1992 |

|

24 |

0 |

4 |

neg |

28 |

|

1993 |

|

26 |

2 |

4 |

neg |

32 |

|

1998 |

|

26 |

9 |

5 |

2 |

42 |

***Figures taken from the Chemical Economics Handbook

The world production has more than tripled in

the last three decades while consumption in the U.S. only grew 60%. This is due the great increase of consumption

in Western Europe and growth in Japan.

The uses of this consumption is largely for the production of paper

electrical uses, as insulators in dry transformers, motors, and transformers

which account for 49% of all U.S. consumption.

In the textile industry, fire resistant fabric accounts for 19% and

filtration 17% of all U.S. consumption.

Overall, the expected annual growth rate for meta-aramids is suppose to

average 3% a year until 2003. The

textile industry is responsible for the production of fire-resistant clothing

and seat covering in airline seats. It

also has established a market in asbestos replacement, thermal insulation and

as a fiber that prevent static electricity buildup. The prices for meta-aramid fibers range

greatly. The staple 1.5-denier fiber cost $11.50 per pound while continuous

filament yarn of 200 denier cost $25.00 per pound. Even more, 1,200 denier filament yarn costs

39.00 per pound!

Summary

In this paper, I have dissected the

chemistry and the growing markets of the specialty fibers Kevlar and

Nomex. Each of these fibers has shown

extensive growth over the last few decades with growth expected to continue

over the next several years. This poses

the question on whether we should expand into these markets and capitalize on

this growth or sit by the wayside. In my

opinion, the outlook for polyamids such as Kevlar and Nomex aramids is very

good. Du Pont, an established company

whose products are well known and trusted, dominates the production of these

fibers. Over the next several years, Du

Pont is going to profit from the production of these fibers. With the established name brand and quality

that Du Pont already holds, the barriers to enter the market are too great for

any company to start up and take their strangle hold over the aramid

market. The invention of these fibers

grew from the research from making very basic items into one of the most

structurally sound products made today.

Bibliography

“Aramids.” About.com.

1996. <http://composite.about.com/industry/composite/gi/dynamic/offsite.htm?site=http%3A%2F%2Fwww.psrc.usm.edu%2Fmacrog%2Faramid.htm> (15 Nov. 2000)

Chang,

Alen: Hung, Richard; Lew, Katherine, Function and Performance of Kevlar, pdf

file, http://www.mse.berkeley.edu/classes/matsci102/Kevlar.pdf

Du

Pont Website:

“Kevlar” <http://www.dupont.com/afs/kfeatures.htm> (15 Nov. 2000).

Du Pont Website: “Nomex” < http://www.dupont.com/nomex/> (15 Nov. 2000).

“Flame

Retardants.” Ullmann’s Encyclopedia of Industrial Chemistry. 1988. Vol

11.

GE website:

http://www.complas.com/kevlar.asp

Groce,

Donald F. “Cotton, Nylon, Lycra Spandex and Allergies.” Latex Allergy News. Sept.

1996. <http://latexallergylinks.tripod.com/lycra.html> (15 Nov. 2000)

“Polyamides

(General)” Encyclopedia of Chemical Technology. 1996 ed. Vol. 19.

p.506-508, 519-523.

Reisch,

Marc. “What’s that Stuff?” Chemical and Engineering News. 15 Feb 1999

<http://pubs.acs.org/cen/whatstuff/stuff/7707scitek4.html> (15 Nov. 2000)

“Spandex

Fiber (Elastane).” Fibersource. <http://www.fibersource.com/f-tutor/spandex.htm>

(November 2000).

“Specialty

Organic Fibers” Chemical Economics Handbook. 1999 ed. 542.7003,

542.7000.

University

of Missouri-Rolla website: http://www.umr.edu/~wlf/Synthesis/kevlar.html

Last

Updated: 30 April 2001