Zeolites and Catalysts: A Physical Chemistry perspective

By Adam Harder

If a zeolite

is strongly heated the absorbed water escapes just as if the stone is

boiling. Hence the term zeolite, which

is formed from Greek words meaning boiling stone. Zeolites are crystalline, hydrated aluminosilicates with a

framework structure. Their three-dimensional polyanionic networks are

constructed of SiO2 and AlO4 tetrahedra linked through

oxygen atoms. Depending on the

structure type, they have regular voids containing cations and water molecules

which are mobile and can be exchanged[1].

This ability to absorb and exchange ions and other molecules is what

makes zeolites such a big part of the chemical industry. The purpose of this paper is to briefly

summarize the chemistry and applications of zeolites used in industry today.

The

structure of zeolite crystals can be represented as a plurality of tetrahedra,

each of which consists of four oxygen atoms surrounding a smaller silicon or

aluminum atom. Each oxygen atom of a

tetrahedron can combine with another silicon or aluminum atom, which, in turn

forms a tetrahedron with four oxygen atoms.

Thus a solid lattice is built up from multiple tetrahedra[1]. The (-Si-O-Al-) linkages form surface pores

of uniform diameter and enclose regular internal cavities and channels of

discrete sizes and shapes, depending on the chemical composition and crystal

structure of the specific zeolite involved.

The enclosed cavities contain both metal cations and water

molecules. The cations are loosely

bound to the lattice and thus can engage in ion exchange. The water molecules can also be reversibly

driven off in most zeolites. The

regular nature of the pores and their apertures enables zeolites to function as

molecular sieves. This is the

outstanding property of zeolites that gives them their value as selective

adsorbents for separating substances and as shape-selective catalysts. Depending on the zeolite type and its pore

system, molecules can enter into the cavity system or be excluded from it. Most of the chemical and physical properties

of the zeolites, and hence their areas of use, are essentially determined by

the aluminum content of their frameworks.

In the literature, this is usually expressed by the Si/Al or SiO2/Al2O3

ratio. The surface selectivity of the

zeolites as adsorbents depends on this ratio. Aluminum-rich zeolites adsorb

strongly polar molecules, while increasing the silicon content leads to

increasingly hydrophobic character[2].

Many

synthetic zeolites also occur naturally as minerals. However, zeolites only became of industrial importance in the

1950’s, when synthetic examples became available on an industrial scale. When talking about the industrial use of

zeolites it is useful to break them down into three basic types: type A, type

X, and type Y. Typical chemical

compositions of these types are shown below.

Type A Na12(AlO2)12(SiO2)12

· 27H2O

Type

X Na86(AlO2)86(SiO2)106

· 264H2O

Type Y Na66(AlO2)56(SiO2)136

· 250H2O

_______________

[3]

The zeolite’s

pore size and shape determine the size of the molecules that can enter the

zeolite interior. Type A zeolites have

a pore diameter such that it is an excellent exchanger of calcium ions and are

consequently used as detergent builders.

Types X and Y zeolites have larger pore sizes than type A. In addition to the effect of the surface

pores in restricting the size and shape of molecules entering and leaving the

zeolite, the size and shape of the internal cavities determine which transition

states are allowed in a reaction and which products can be formed[2]. Consequently the type X and Y zeolites are

used as catalysts in the catalytic cracking of petroleum, the largest zeolite

catalyst market. Today the type Y

zeolites have taken over this market due to their higher thermal stability

caused by their relatively higher silica/alumina ratio.

Although

there are many processes for zeolite synthesis, most commercial zeolite

production can be categorized into two main types of processes:

¨The

formation and crystallization of the zeolite from basic raw materials, via sols

or an aluminosilicate hydrogel.

¨The

crystallization of the zeolite in situ from calcined kaolin clay.

Hydrogel/Sol Processes

Typical sodium zeolites are formed by the crystallization

of sodium aluminosilicate prepared from pure sodium aluminate, sodium silicate,

and sodium hydroxide solutions.

NaOH +

NaAl(OH)4 + Na2SiO3 + H2O

¯

[(Na)a(AlO2)b(SiO2)c

· NaOH · H2O]gel

¯

(Na)m[(AlO2)m(SiO2)n]

· pH2O + mother

liquor

Factors affecting the type and

structure of the zeolite formed include the crystallization temperature and

length of time that the gel is maintained at that temperature, the

silica/alumina ratio of the reaction mixture, and the size and type of cation

present[3].

Kaolin

Conversion Process

Kaolin clay can also be used as a source of alumina and

silica for zeolite synthesis. For

example, meta-kaolin is produced by calcining kaolin at 500-600°C. Zeolite A is then formed by the reaction of

meta-kaolin with aqueous sodium hydroxide.

A source of additional silica, such as sodium silicate, is required for

production of type X and Y zeolites with this method[3].

The applications of synthetic zeolites then, can be broken

down into three major categories: zeolites as detergent builders, zeolites used

for adsorption and separations, and zeolites as catalysts. For the purposes of this paper I will focus

on the use of zeolites as catalysts.

The use of zeolites as heterogeneous catalysts is most

important in there use in oil-refining processes. The most important is fluid catalytic cracking (FCC), which

converts vacuum distillates and residues into gaseous alkenes, gasolines, and

diesel fuel. Type Y zeolites have been

used as active components in the FCC process since 1964. These materials constitute 5-40% of the

catalyst. Zeolite catalysts have higher

activity and give higher gasoline yields and less coke formation than the

amorphous alumina-silica and high-alumina catalysts formerly used. The presence of sodium ions in the zeolite

would deactivate the catalyst, so most of the sodium is removed by exchange

with ammonium and/or rare earth cations.

These catalysts can then be calcined to drive off ammonia, producing a

hydrogen ion-exchanged zeolite with a smaller unit cell volume than

conventional type Y zeolites. The rare

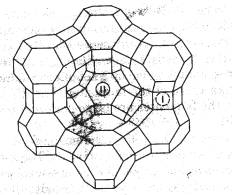

earth elements provide stability and high catalytic efficiency. The framework structure of these zeolites

creates intracrystalline pores called supercages, each with a diameter of about

1.2 nm. The pore structure is three

dimensional, and the supercages are connected by apertures with diameters of

about 0.74 nm[4]. These cages and

apertures allow a zeolite catalyst to be size selective, so it can “choose”

which sized molecules it wants to catalyze. Some rather large molecules can fit

through these apertures and undergo catalytic reaction in the cages.

-Figure 1: Diagram of a

Zeolite Supercage[4].

The zeolite

frame is made up of SiO4 tetrahedra, which are neutral, and AlO4

tetrahedra, which have a charge of –1.

The charge of the AlO4 tetrahedra is balanced by the charges

of additional cations that exist at various crystallographically defined

positions within the zeolite. Zeolites

are thus ion exchangers, and the cations may be catalytically active. Analyzing

catalytic activity requires the computation of factors controlling reactions at

the catalytic sites in the zeolite. The electronic properties of the system are

thus critical.

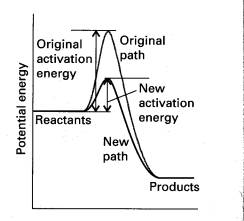

Zeolite catalysts effect reactions in a number of

ways. For reactions with big activation

energies, such as in the catalytic cracking of petroleum, you would normally

need to add a large amount of energy to make the reaction proceed at any

reasonable rate. Introducing a catalyst

to the same reaction reduces the activation energy and allows the reaction to

go at a much faster rate without the need for the addition of extensive amounts

of energy. For then a higher proportion

of molecules are able to pass over the activation barrier.

-Figure 2:

Potential Energy vs. Time[5].

Although the new route is faster, the

initial reactants and final products are the same. We know that G is a state function, so ΔGrӨ has the same value however the

reaction is brought about. Therefore,

an alternative pathway between reactants and products leaves ΔGrӨ, and

therefore K, unchanged[5]. That is the

presence of a zeolite catalyst does not change the equilibrium constant of the

reaction.

Overall, zeolites are very useful in

the process of separating petroleum into its different C fractions. They are size selective catalysts, which

gives them the advantage of being able to choose which C fractions to

separate. By changing the cations

present in their structure zeolites can be used to catalyze many other

reactions as well.

Bibliography

[1] L.W. Cod,

K. Dijkhoff, C.J. van Oss, H.G. Roebersen, E.G. Stanford (eds.): Chemical Technology: An Encyclopedic

Treatment, Vol 1, Barnes & Noble Inc., New York (1968) 136-137

[2] E. Roland, P. Kleinschmit, A.G. Degussa, Z.N.

Wolfgang, et al, “Zeolites,” Ullmann’s

Encyclopedia of Industrial Chemistry, Vol A28, VCH (1996) 475-500

[3] M. Smart,

T Esker, A. Leder, K. Sakota, “CEH Marketing Report: Zeolites,” Chemical Economics Handbook, SRI

International (1999) 599.1000A-599.1002U

[4] J. I.

Kroschwitz, M. Howe-Grant, et al, Encyclopedia of Chemical Technology: 4th

Ed, Vol 5, John Wiley and Sons Inc., (1993) 358-445

[5] P. Atkins,

The Elements of Physical Chemistry: with Applications in Biology, 3rd

Ed, W. H. Freeman and Co., New York, (2000) 158-238